Products

- Slip Ring

- Photoelectric slip ring

- Cap type conductive slip ring

- Hollow shaft conductive slip ring

- Optical fiber slip ring

- Disc conductive slip ring

Electric Slip Rings

Electrical slip ring is a rotating assembly that could transfer power, control circuits or data (analog / digital) during 360° rotating, including capsule slip ring, miniature slip ring, through bore slip ring, high power slip ring and pancake slip ring, etc. Electrical slip ring can be combined with other medium for transmission, such as Gas+Electrical slip ring, Fluid+Electrical slip ring, RF+Electrical slip ring, Fiber optic+Electrical slip ring, etc.

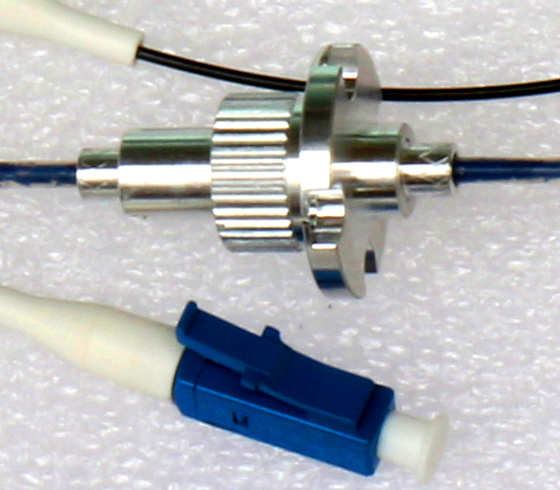

Fiber-Electric Slip Rings

Fiber-Electric slip ring is a combined Fiber Optic Rotary Joint and electrical solution, suitable for some applications which require to high-speed signal, mass data, high accuracy, and long-distance transmission from stationary inlets to rotating outlets.

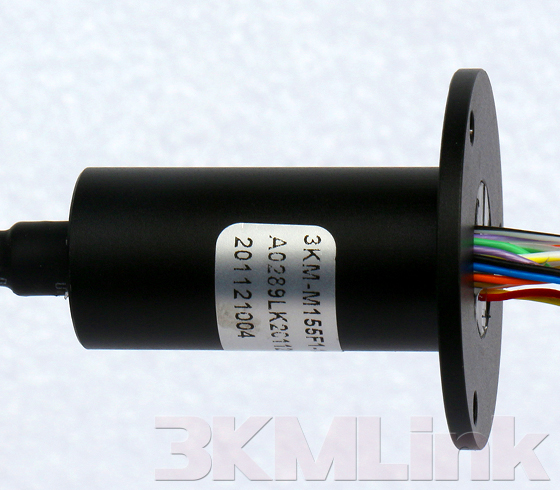

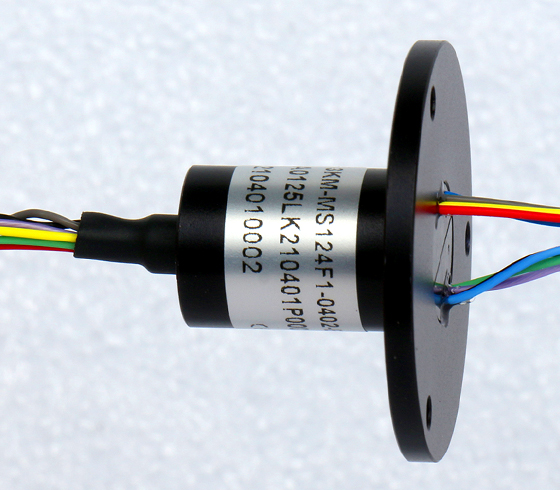

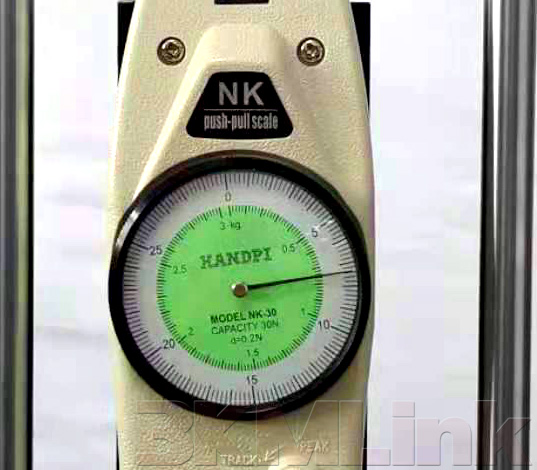

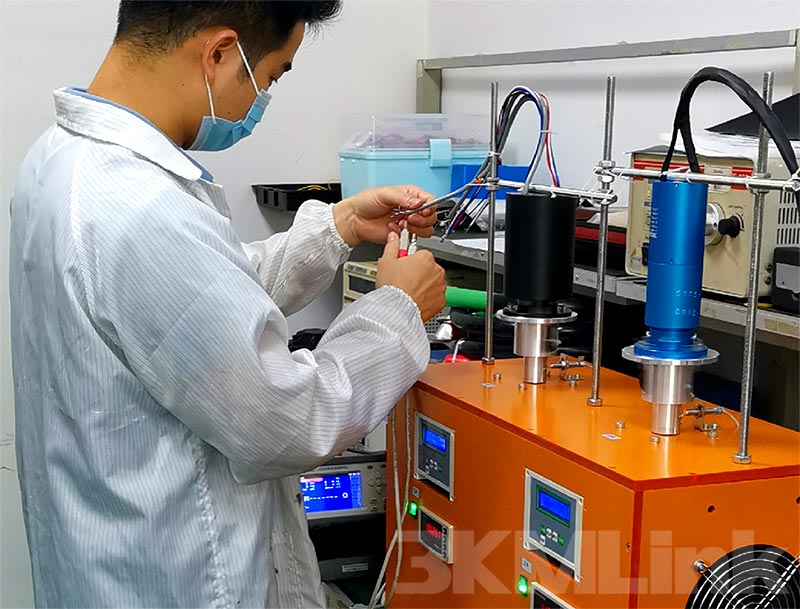

Capsule Slip Rings

Capsule slip rings are designed with flange, 3KM C-series have undergone subversive innovations in terms of structural design, production process, assembly process, performance testing, etc. The key node processes have all realized automated production, eliminating the artificial destruction of consistency during production and installation.

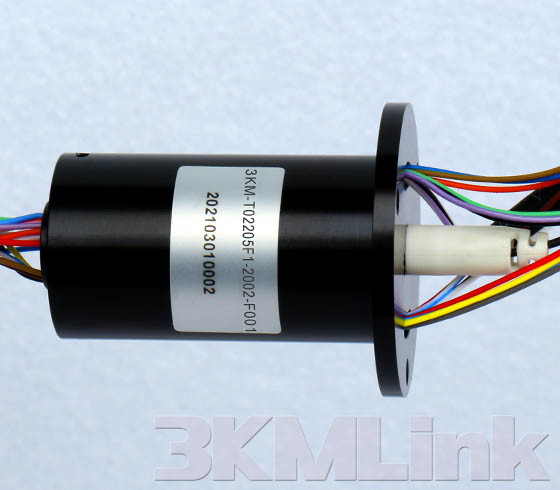

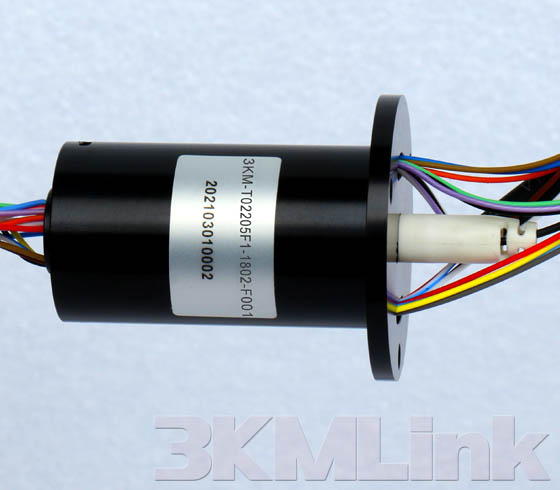

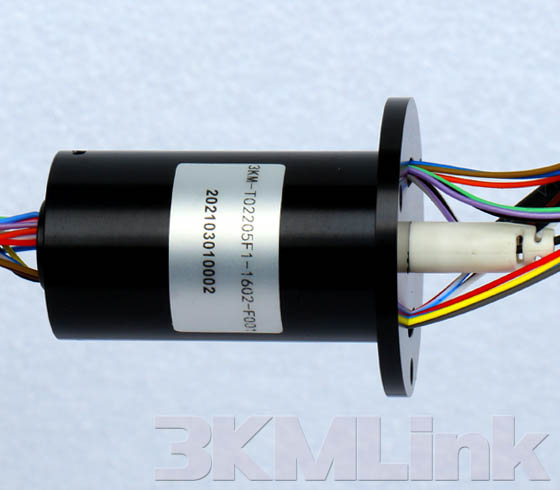

Through Bore Slip Ring

3KM T-series slip ring is designed with a through hole for shaft mounting, the through hole sizes are from 12.7mm to 124.6mm. it could be applied to transmit power, signals, RF, gas and fluid when the devices require 360° rotating.

T-series incorporates cluster brush structure, multi-point uniform contact structure design for each signal, to prevent the phenomenon of packet loss in high-speed rotation of the transmission signal.

Super hard precious metal surface treatment technology, strength, hardness and conductivity are superior to the international military standards hardness.

光纤滑环

Fiber Optic Slip Ring is a rotating assembly that could transfer electricity and Fiber signal during 360° rotating,The fiber optic slip ring is fully sealed, and the optical signal adopts non-contact and independent propagation, which will not cause interference to electrical signals, nor is it immune to electromagnetic interference, and is highly adaptable to the application environment, such as low temperature, high pressure and electromagnetic interference, with a long-life span.

Pancake Slip Rings

The pancake slip ring is a slip ring in which the brush wires and ring channels are designed in a flat concentric circular shape. Its multi-channel brush wires and ring channels are radially distributed from the inside to the outside on the same plane. The height can be as small as 5mm, pancake slip ring is designed for somewhere vertical space is limited while horizontal space is less restrictive.