Analysis on the hidden dangers of using lubricating grease in electric slip rings 2021-07-09

In order to avoid the hidden danger of causing short circuits, the lubricating grease used in the slip ring must be insulated. Moreover, lubricating grease will only reduce the electrical conductivity of the slip ring contacts, and will never increase the electrical conductivity.

Introduction to the advantages and disadvantages of the brush process of electric slip ring 2021-06-17

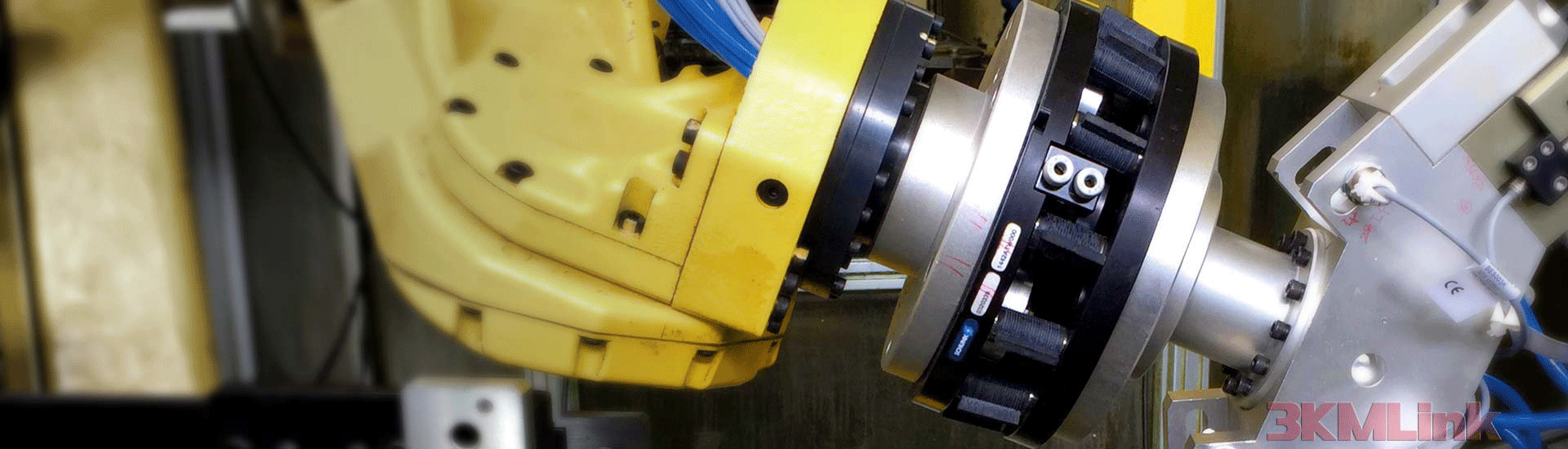

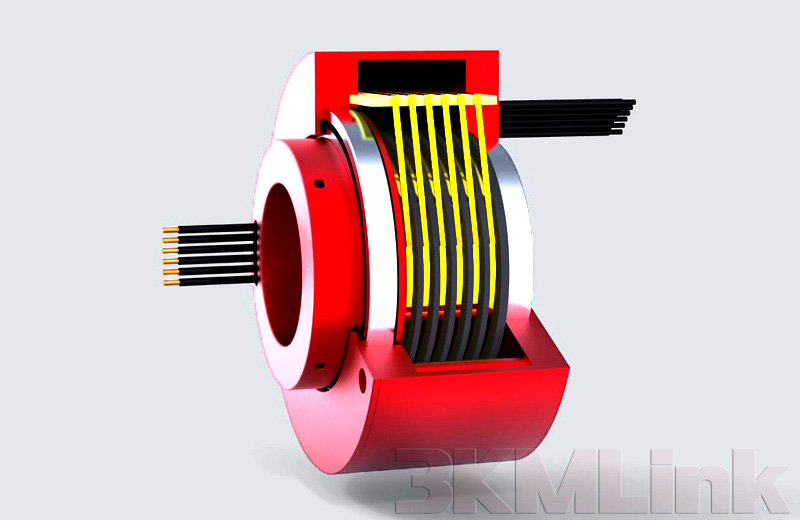

Slip ring is a rotating connection componentof electric power, signal and other media composed of rotating (rotor) and stationary (stator)device.Electriccurrent and signal are connected and transmitted through brushes. Therefore, the performance of the brush determines the performance quality of the entire slip ring. Different types of slip rings require different materials and types of brushes, and each has its own characteristics.

How do slip rings work? 2021-06-17

For the slip ring, the whole is realized by the principle of elastic lap, rolling lap and sealing, combined with precise and ingenious movement structure design, sealing structure design, precise part manufacturing coordination, and reasonable material selection to build a stable and reliable structure. Simply attach the slip ring to an infinitely rotating device to provide power to the rotating part, so that the rotating part can perform other transmission tasks while infinitely rotating.

The role and selection of lubricating grease for slip ring 2021-05-30

If conductive grease is applied to the slip ring contacts, those fine surfaces that do not touch each other become conductors, and the contact resistance is greatly reduced, thereby enhancing the electrical conductivity of the contacts and the device.