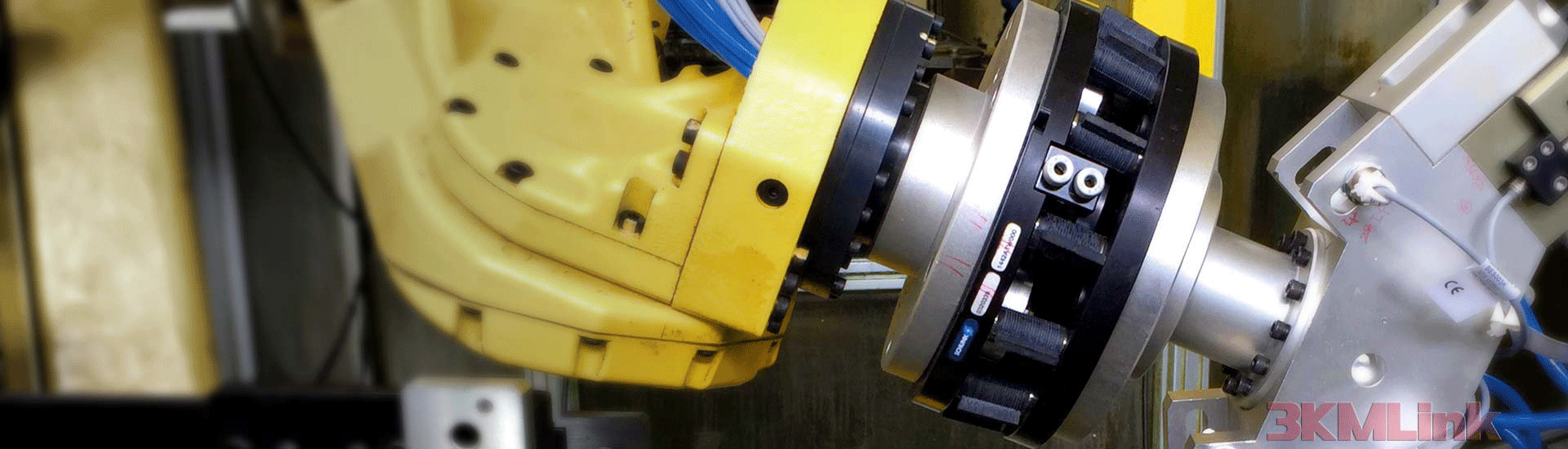

Limit life detection of conductive slip ring

The limit life test of conductive slip ring is to operate continuously for 24 hours under the set speed state until the transmission signal of conductive slip ring fails. 3000 meters connect all newly developed conductive slip rings, which must undergo small batch limit life test to verify the relationship between the actual life of the product and the design life

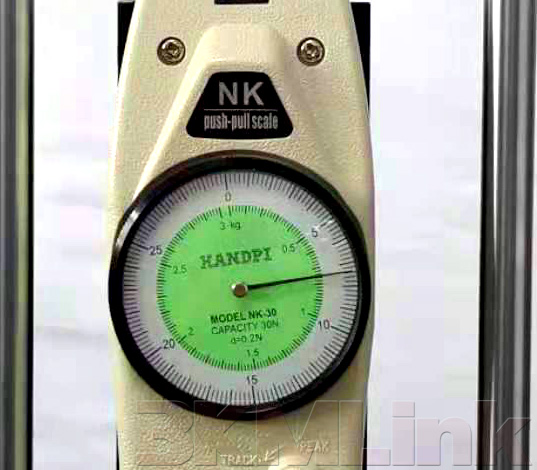

Slip ring pull-off force detection

It is used to detect the pull-off force of the brush wire, loop, solder joint, terminal and other parts of the electric slip ring.

The inspection and testing machine calibrate the torque of the electric slip ring to determine whether the sample meets the torque requirement.

Gas electric slip ring sealing (gas leakage) inspection

Tightness (leakage) inspection is the most important part of the gas+electric slip ring. Put the gas electric slip ring into the water at 5-10 cm for 10 seconds, turn on the 1Mpa air pressure, and keep rotating the gas electric slip ring back and forth for 20 seconds, and observe whether there are bubbles emerging during the whole process.