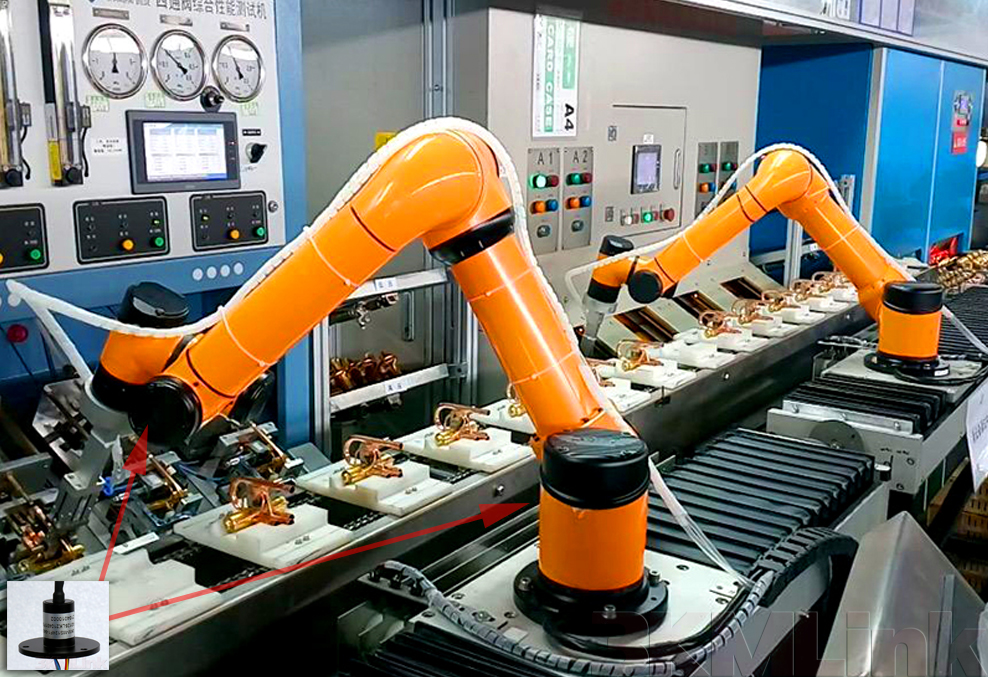

The application of collaborative robots and robotic arm

In today’s era of intelligent manufacturing, whether it is an industrial manipulator, a collaborative robot, or a commercial or consumer-grade robot, it must be equipped with a 360° unrestricted rotation transmission control current, analog signal, digital signal, gas, fluid and other media. Therefore, slip rings are widely used in the key components of modern robots such as mechanical structure systems, drive systems, perception systems, and interactive systems, and have become an indispensable component for robots to achieve intelligence, automation, and personification.

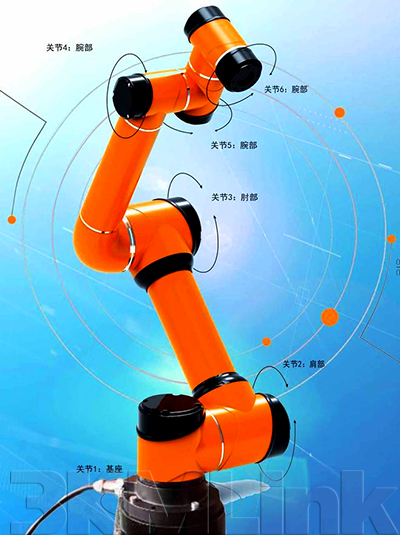

In terms of the rapid development of collaborative robots in recent years, its flexibility has surpassed that of human hands. For example, the collaborative robot supports a variety of installation positions such as formal, inverted, and side-mounted. Each of its joints can achieve 360° rotation, and can operate in all directions in the basic spherical working area, with almost no blind spots.

Collaborative robots generally have 3 to 6 axis joints, and each joint requires 360° unrestricted rotation, which means that each collaborative robot needs at least 3 to 6 conductive slip rings. From the perspective of market applications, although collaborative robots are still dominated by the B-end market of automobiles, electronics, medicine, food, textiles, furniture, etc., With its intelligent and lightweight development, it is bound to gradually penetrate into the C-end market of education, service, display and other commercial terminals and home individuals.

Collaborative robots will gradually develop from the relatively simple tasks of grasping, assembling, welding, finishing, and spraying to a series of intelligent and complex tasks such as inspection, inspection, analysis, and medical treatment. Due to the different division of labor of each collaborative robot, it must be applied to slip rings of various combinations such as electric slip rings, photoelectric slip rings, and radio frequency slip rings.

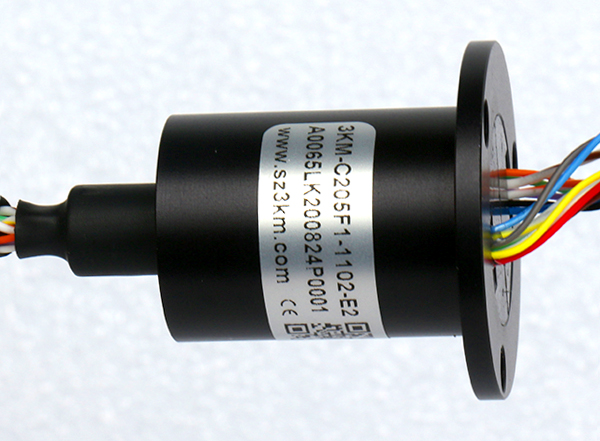

Aiming at the requirements of compact structure, light weight, and high flexibility of collaborative robots, our miniature capsule slip ring is not only small size, but also due to the use of fully automated production, it avoids the defects caused by human factors in the production process. The dual-guarantee structure design of multiple contacts ensures extremely high consistency, reliability, and extremely low packet loss rate, which fully meets the high-quality control current, optical signal, and digital signal transmission requirements of the collaborative robot.

Features:

● Automated production to ensure a high degree of consistency and stability

● Innovative loop and brush wire design, dynamic resistance change value <0.005Ω

● Unique single-channel multi-point touch design, signal transmission is more stable and reliable

● High rotation accuracy, high wear resistance, corrosion resistance, stainless steel miniature bearings

● A variety of simultaneous transmission of control power, digital signals, radio frequency signals, gas, fluid and other media.