The application on heavy infrastructure construction machinery

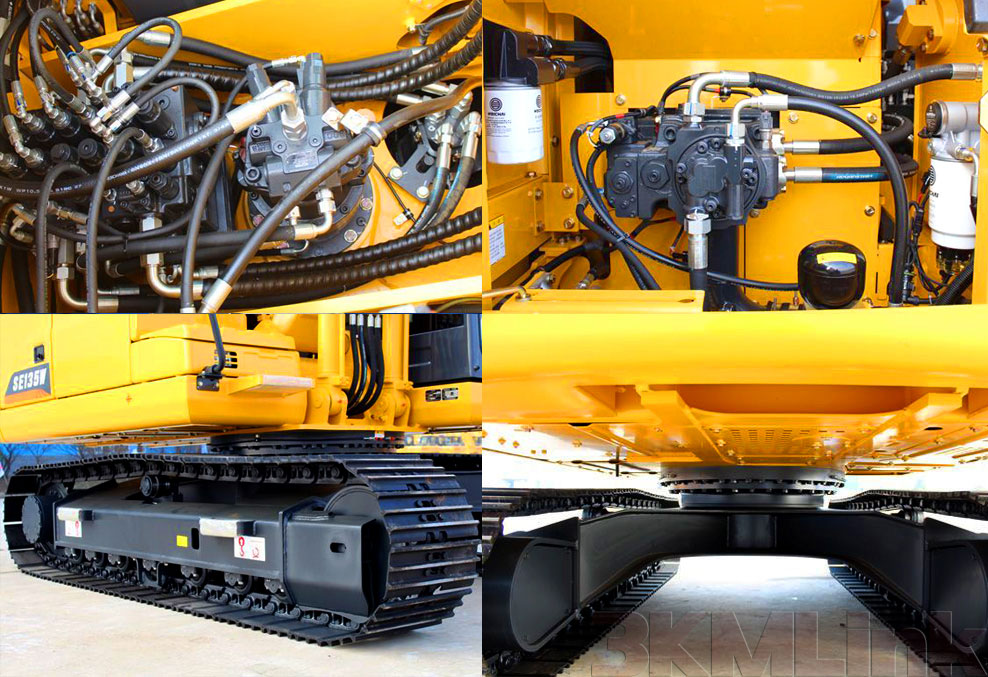

Loaders, excavators, cranes, cranes, shield machines, marine machinery, rescue trains, high-altitude operating vehicles and other heavy engineering machinery and equipment are integrated with 360° rotating parts. When they work, most of them need to use various slip rings to rotate and transmit current, voltage, gas, fluid and various signals.

For example, the electric slip rings of cranes are mainly installed on the slewing center for the mutual transmission of power and signals between the crane and the truck; the electric fluid combined slip rings of excavators and loaders are installed between the cab and the track. During the transmission of signals, air pressure, hydraulic pressure and kinetic energy, the excavator can rotate 360 degrees.

The application of slip rings in construction machinery

The application environment of slip rings in construction machinery is mostly very harsh and complex, including high and low temperature, high humidity, salt spray, oil, dirt and sewage, severe vibration and even collision. Therefore, the slip ring of construction machinery has special requirements for the protection level of water discharge, dustproof and anti-impact, as well as anti-vibration, high and low temperature resistance, and corrosion resistance.

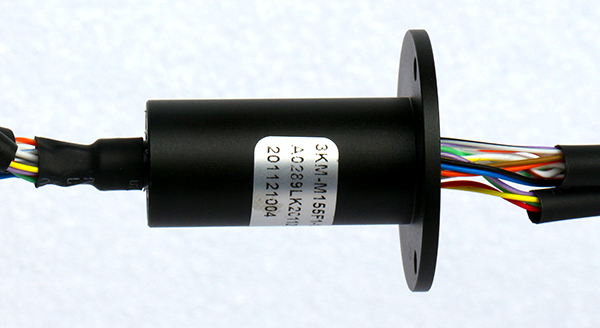

Our engineering machinery electric slip rings not only have extremely high consistency and stability, but also carry out high-strength simulation tests for slip rings in different application environments, including high-low-temperature and high-humidity cycle impact test of slip ring, multi-angle long-time high-intensity vibration test, wire pull-off force test, temperature cycle high-pressure breakdown test, brush wire conduction resistance high and low temperature test, etc., to ensure slip ring can still work safely and normally in harsh outdoor environments.

Features:

● Applicable to various heavy construction machinery and equipment such as lifting, excavating, drilling, etc.

● Compact structure, quick connector design, flexible installation and high reliability

● Special sealing structure, protection level up to IP68

● High anti-seismic technology all-metal shell structure design, anti-seismic strength ≥4.5G

● Thoroughly solve the requirements of high power output, signal transmission and work in extreme environments

● The power can reach 600A, and the number of signal and circuits connection methods can be customized according to requirements