Standard

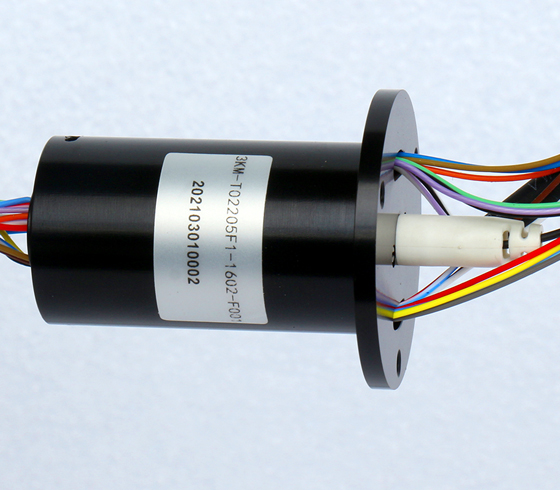

Through Bore Slip Rings

Super hard precious metal surface treatment technology, strength, hardness and conductivity are superior to the international military standards hardness.

Rotary Union

Rotary union is also called pneumatic slip ring or under pressure vacuum slip ring, which can independently rotate 360° to feedthrough single-path, multi-paths gas or under pressure vacuum. Rotary unions allow the feedthrough industrial inert gases such as compressed gas, steam, nitrogen, and chlorine and a variety of other media. Our 3KM LINK rotary unions available single passage of multiple passage 1-24 , The maximum working pressure range is -1.5Kpa~1Mpa.

RF Slip Ring

The high-frequency slip ring has a transmission frequency up to 500 MHz-50GHz, compact structure, stable performance, good shielding effect, strong anti-interference ability, and easy integration into other equipment.

Fiber-Electric Slip Rings

suitable for some applications which require to high-speed signal, mass data, high accuracy, and long-distance transmission from stationary inlets to rotating outlets.

Fiber Optic Slip Rings

The fiber optic slip ring is fully sealed, and the optical signal adopts non-contact and independent propagation, which will not cause interference to electrical signals, nor is it immune to electromagnetic interference, and is highly adaptable to the application environment, such as low temperature, high pressure and electromagnetic interference, with a long-life span.

Capsule Slip Rings

Capsule slip ring is suitable for transferring analog and digital signals. Standard models are available from 6 to 56 circuits.

Electric Slip Rings

including capsule slip ring, miniature slip ring, through bore slip ring, high power slip ring and pancake slip ring, etc

Pancake Slip Rings

The height can be as small as 5mm, pancake slip ring is designed for somewhere vertical space is limited while horizontal space is less restrictive.

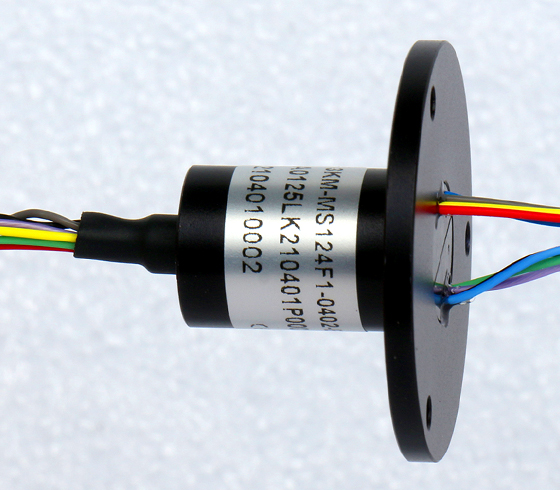

Miniature Slip Rings

It will not affect its normal operation and performance.Our miniature slip ring adopts fully automated production to ensure the consistency of the slip ring and the maximum accuracy to achieve its optimal design value, thereby prolonging the service life of the slip ring.

High Current Slip Rings

High current slip ring uses graphite carbon brushes with excellent self-lubrication and wear resistance that have been treated at a high temperature of 2500°C. It has low noise and is protected by a special coating layer.

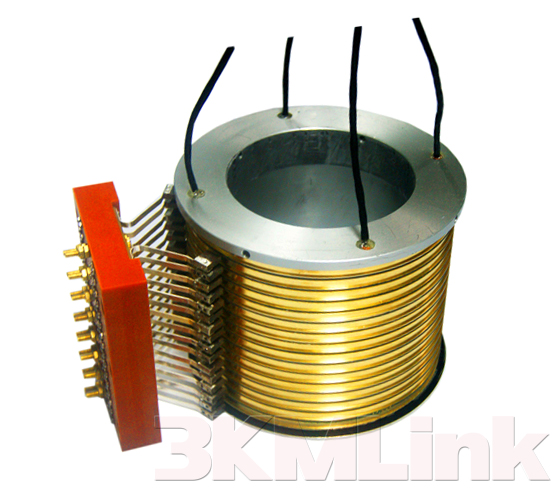

Separate Slip Rings

The advantage of the separated slip ring is that it is flexible and simple, can better adapt to space constraints, and meet some specific installation requirements and special installation environments.

Fluid metal slip ring

3KMLink gallium-based fluid metal slip rings are non-toxic and are suitable for rotating connections on automated production equipment in the food, medical and other industries.

Low Torque Pneumatic Slip Ring